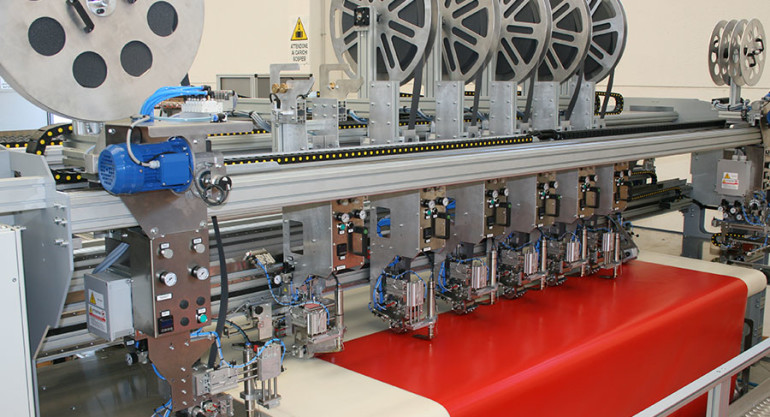

SMRE model : SM-321-TA MULTIPLE TOOL DIGITAL WELDING STATION

CONTINUOUS WELDING OF SPECIALTY FABRICS

7 Tons of engineering brilliance

After a decade of experience in designing and building heavy duty welding and cutting machines to process flexible PVC we introduced SM-321-HA, a multiple tool digital welding station for the full-automatic production of tarpaulins, truck covers and roofs, and pergolas.

SM-321-HA caused a revolution in the truck cover industry by drastically reducing the necessary cycle time and number of operators needed for the job. Since its introduction in 2010 the machine has seen several upgrades that make it the fastest, most efficient manufacturing solution for quality tarpaulins available on the market today. With its unparalleled welding quality and exceptional productivity, its wide variety of cutting and welding tools and accessories, SM-321-HA is a machine unlike any other on the market.

A range of specifically designed software programs make SM-321-HA a complete manufacturing solution for your production requirements. It will streamline your production processes and deliver the efficiency and quality you are looking for.

Contact us for a custom made offer.

HIGHLY PROFESSIONAL PRODUCTS

UNCOMPROMISING QUALITY

- Continuous production cycles

- Exceptional productivity

- High speed welding

- High level of automation

- Drastic reduction of man power

- Creation of very large products in a limited space

- A choice of precision welding tools to apply a wide variety of profiles

- Heavy duty industrial structure

- Highly customizable

- Multiple layer heat resistant conveyor belt

- Superior control systems

- Precision mechanics

- Top quality electronics

- High precision

- Extremely small tolerances even on great lengths

- Vacuum power for total fabric control

- Unparalleled welding quality

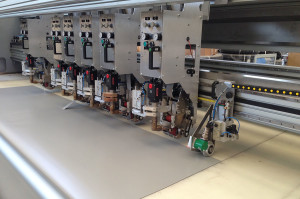

INDUSTRIAL WELDING AND CUTTING TOOLS

Welding heads for vertical or horizontal reinforcing straps U41 (3)

Horizontal welding heads apply the (50 mm) reinforcing straps in length direction. Vertical welding heads apply (50 mm) straps over the width of the fabric. Welding wheels feature the patented Intelligent Torque technology – the digital control of the tension of the welded straps and the PVC panel during the production cycle – to ensure perfectly flat and incredibly strong seams and extremely high precision even on great lengths. The vertical head is available in a high power version for extremely fast welds, providing a significant reduction of the overall cycle time.

Welding heads for vertical or horizontal anti-vandalism straps U48 (2)

Can apply a wide range of different straps – even the anti-vandalism PVC straps with steel cable. With the Intelligent Torque technology, these otherwise hard to manage profiles are applied horizontally or vertically with great precision and unparalleled welding strength. These welding heads are available is an adapted version that allow the application of omega profiles for the production of pergolas.

Welding heads for horizontal omega profiles U105

Designed for the application of omega profiles on PVC panels for the automatic production of pergolas on infinite lengths. The Intelligent Torque technology allows a perfectly flat welds of the large omega profiles. Precision and strength of the seams is guaranteed.

Welding heads for horizontal hems, pockets or pockets-with-rope U43

Fold the fabric and automatically create a hem or pocket on the edge of the tarpaulin. For the production of truck roofs the fabric guides can be designed for the automatic insertion of a rope during the welding cycle.

Double welding heads for wide horizontal straps U42

Feature a twin heating system and double hot air output and are used to apply wide horizontal reinforcing straps on the tarpaulin. Welding of the horizontal straps is done continuously, while the fabric is fed into the machine.

Double welding heads for wide vertical straps U42 (8)

These very large welding tools run in between a double tool bridge and feature a twin heating system with double air output. Adaptable to process straps of variable width. Motorized welding wheels for total fabric control and perfectly flat, extremely strong seams.

Double welding heads to apply the butterfly straps U47 (2)

Feature a digital control system that ensures that the butterflies – regardless whether there are 3 or 5 in a tarp width – are always perfectly in line over the full length of the tarpaulin. Ensures unparalleled precision in the weld for a highly professional finished truck roof.

Motorized blade for the cross cut U45

Performs the last operation of the production cycle by cutting the fabric off of the roll. Makes a fast, very precise cross cut along the width of the machine. With its razor sharp pentagonal blade and high rotating speed the motorized rotary knife can handle even very heavy PVC sheets.

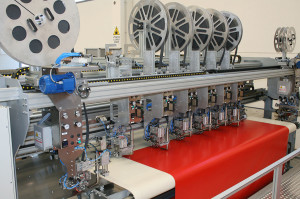

Motorized unwinding system U44 (2)

Allows the processing of heavy rolls of PVC. Automatically feeds the fabric into the machine at a programmable speed, perfectly synchronized with the pulling speed of the machine. Avoids the fabric from stretching during the pull, which would compromise the precision of the finished product. Features digital edge control with twin sensors that read the exact position of the fabric and – if necessary – automatically correct the position of the roll. Features automatic tension control with digitally controlled dancer systems for a very smooth fabric feed.

Multiple layer heat resistant conveyor belt for total fabric control U106

The heat resistant conveyor belt and powerful vacuum turbine ensure total fabric control and a perfect, split-second synchronization of the fabric movement and start-and-stop of the welding heads, allowing the machine to create seams without burning marks even on very light colored fabrics.

MAIN FEATURES

Continuous production cycles

The industrial, heat resistant conveyor belt enables the machine to perform a continuous pull-and-weld operation and work in full automatic cycles. The vacuumed belt and pneumatic rollers pull the fabric off of the roll, the welding, marking and cutting tools do their job until the programmed sequenced is done or until the fabric on the roll finishes.

High speed welding. Exceptional productivity.

With its continuous production cycles the machine is able to create one cover after another, and only stops when the fabric on the roll finishes. The high power vertical welding heads allow for great welding speed and drastically reduce the necessary production time.

High level of automation

Only one operator is needed to supervise the machine during the welding cycles. Instead of needing multiple operators for the multitude of cutting and welding jobs necessary to produce a truck cover, SM-321-HA carries out all steps in the process automatically

Creation of very large shapes in a limited space

With its continuous fabric feeding operation, the industrial conveyor belt allows for the creation of very large patterns in a very limited space. End products of infinite length can easily be created by this machine with very limited footprint.

Heavy duty industrial structure

The exceptional manufacturing performance of SM-321-HA series stems from the symbiosis of superior control systems, a very robust machine structure and components, precision mechanics and highly reliable welding tools. With its sturdy, heat resistant, multiple-layer conveyor belt, SM-321-HA will apply straps in X and Y direction on PVC panels of infinite length. Top of the bill electronic and pneumatic components, high precision tools, and an industrial unwinding system for jumbo rolls complete this machine.

Highly customizable

Whether you first apply a vertical or a horizontal strap, whichever the size of the straps is, whether you apply a specific profile or need to weld a pocket or a hem, SMRE can build the structure, the tools, and the accessories to fit your specific production requirements and allow you to create the end products you desire.

Extremely small tolerances even on great lengths

With its vacuumed conveyor belt and its motorized unwinder with electronic edge correction and digital fabric tension control, straps are applied with absolute precision and the length tolerance is close to zero.

Unparalleled welding quality

The smooth, digitally controlled fabric feed and the patented Intelligent Torque technology on the welding wheels ensure a superior welding quality during the application of all straps – whether these are standard PVC or anti-vandalism profiles with steel cables, or omega profiles for pergolas – in X and Y direction.

SOFTWARE SOLUTIONS SW13 + SW14

SM-321-HA is managed with an easy-to-use software that is operated from a touch screen control panel. The machine imports and reads CAD drawings of the finished product, translates the drawings into welding jobs and sets all vital parameters automatically. To further automate the production cycle, a barcode reading system is available that avoids unskilled operators from having to program the machine. All the operator has to do is point the gun at the barcode, place the material on the conveyor belt, check the correct positioning of the tools, and push the START button.

PRODUCTS AND APPLICATIONS

SM-321-HA enables manufacturers of tarpaulins, lateral truck covers, or truck roofs, to produce finished products of superior quality. Full automatic, highly efficient, and very precise. With an extremely high production output.

94

255

185

105

110

106

Disclaimer

Images and technical features may differ from the actual product. Some of the images may show machines equipped with optional components, tools and/or accessories. SMRE S.p.A. reserves the right to change or modify the product without any prior notice